Any RFID application in the textiles field involves three major components: (a) RFID tags, (b) RFID Reading Devices, and (c) Software platforms. In order for an RFID system to work, the items need to gain a unique identity. This is why the textiles’ RFID tagging represents an important step in implementing any RFID Laundry project.

Currently, RFID tags producers promote three methods of attaching RFID tags to textile items:

- Heat-sealing the RFID tag to the textile item

- Sewing the RFID tag in the hem of the textiles

- Securing the RFID tag inside a pouch.

The challenge

While these are the most common methods used to tag textiles, the above-mentioned methods do not necessarily ease the implementation of the RFID application. This is because they involve several steps and additional costs for the Laundry, especially when the textile items are already running in the Laundry-Client circuit.

To heat-seal the RFID tag to the item, the Laundry Unit has to purchase a heat seal press. Also, they need to have trained staff to use the tool, and of course, the tagging of the textiles is difficult when the textile items are already in circulation.

The same goes for sewing the RFID tag in the hem of the textiles. The Laundry would need sewing machines and trained staff for it. Yet the most important is that neither of these methods allows attaching the RFID tags to textiles without causing delivery delays due to the time required to tag the textiles in the Laundry-Client circuit, especially when the Client owns the textile items.

The solution

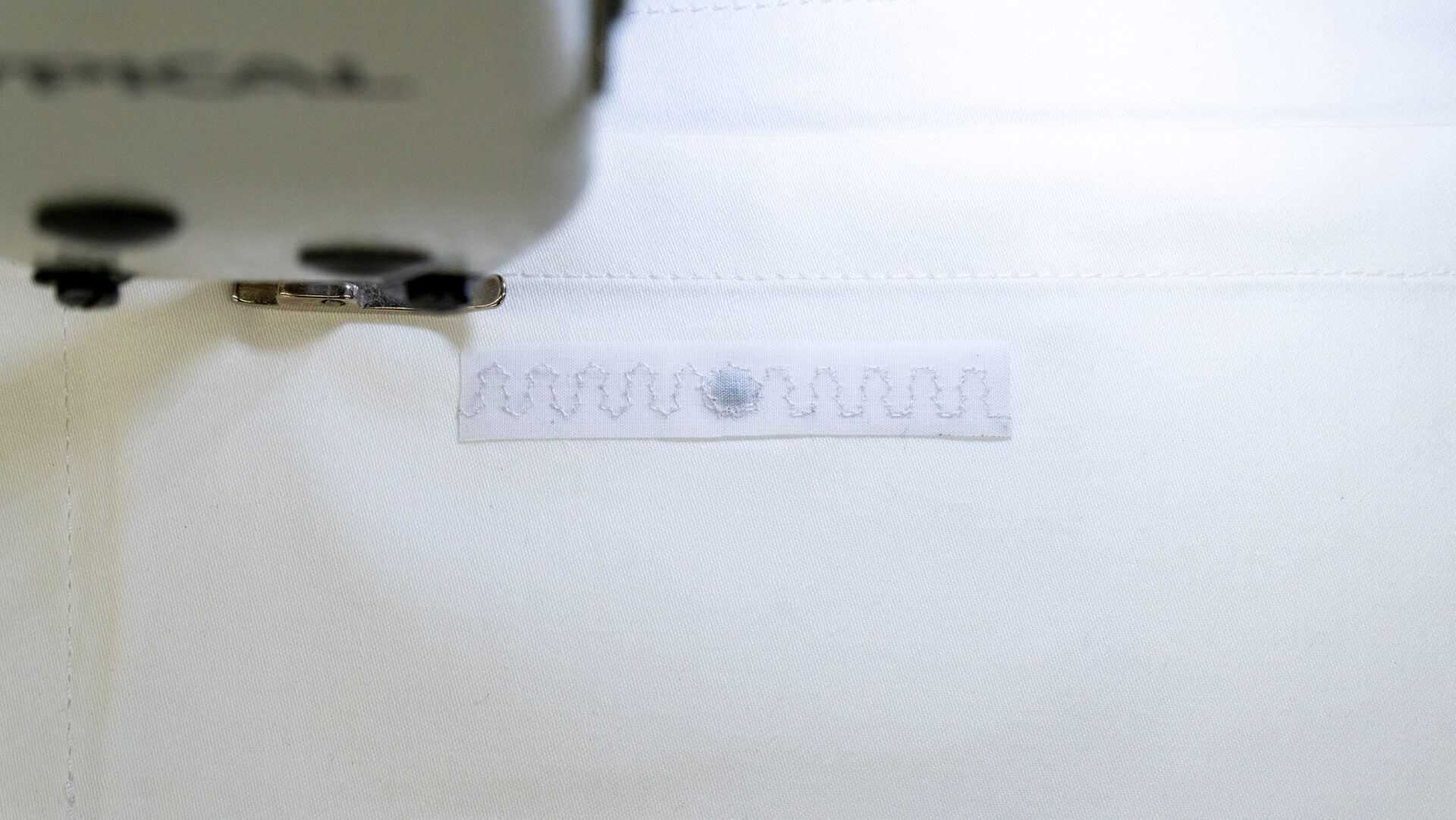

The KTS team insisted on overcoming these challenges and easing out the work a Laundry Unit has to do to implement the RFID technology in their business. Thus, we developed DAC 700, a new RFID threadlike laundry tag that allows the simple yet most practical attaching method to the textiles, with no sewing machine or heat seal press needed. The threadlike form of our new RFID tag permits its manual insertion in the hem of the textiles with a crochet hook in a matter of seconds. This means that the RFID tagging of textiles can now be done easier, without the textiles leaving the Laundry-Client circuit. Moreover, due to the unique and simple method introduced, the end clients (end-users) can perform the RFID tagging of the textiles by themselves.

We will present this new RFID tag and its unique attaching method at the upcoming EXPOdetergo International 2022, in Milano, Italy. You can find out more by visiting our stand, N29 in Hall 3P, between 21-24 October 2022.

We look forward to meeting you there!

The KTS Team